|

Editorial contact: Upfront Design Decisions Critical to Profits Boothroyd Dewhurst urges product manufacturers to reinvest in early design WAKEFIELD, R.I., USA, June 23, 2008 – Manufacturers can cut total design time 40 percent by implementing Design for Manufacture and Assembly (DFMA) methodologies early in the product development process, Nick Dewhurst, Executive Vice President of Boothroyd Dewhurst, told attendees at the company’s 23rd annual DFMA Forum this month.

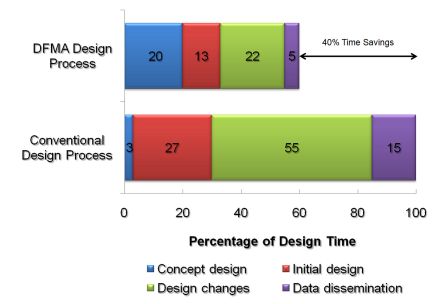

Dewhurst presented a bar chart (see Figure 1) showing percentage of design time spent using DFMA versus the conventional design process. “You see a 40 percent time savings with DFMA,” he said. “If you don’t spend the time early, it comes back at you later in the form of design changes you could have avoided.” “Companies need to reinvest in design to meet the market drive toward quicker release of products,” Dewhurst said. “By designing and engineering products with DFMA efficiently up front, they can meet innovation, quality and time-to-market targets and avoid engineering change orders and wasted prototypes later in the process.” DFMA software is used to quantify manufacturing and assembly costs early in the development process to cut labor, part and operational costs, and benchmark competitive designs. The theme of this year’s Providence, R.I. event, considered the foremost conference worldwide on DFMA methodologies for product developers, was “DFMA Today: Leading the Way to Results.” Participants in the 2008 Forum included Motorola, Hypertherm, Zhivago Marketing Partners, The Genlyte Group, Gerber Scientific, Harris Corporation, Kulicke & Soffa Ind., SolidWorks, EOS, BMA, The Raymond Corporation, UniRac, NH Precision Metal Fabricators and The Boeing Company. Many reported significant gains in profitability resulting from DFMA-based design engineering programs. Among the more outstanding results was a 600 percent increase in profit per square foot of factory floor space and a 75 percent decrease in warranty cost per unit, detailed by Dewhurst’s co-presenter, Mike Shipulski of Hypertherm, Inc. “DFMA is more than a design software tool,” said Shipulski. “It contains answers to most of the questions that need to be addressed to maximize the profitability of the entire supply chain.” Part-count reduction, a fundamental DFMA tenet, plays a major

role in the methodology. Some highlights of the Forum:

“The messages we heard from this year’s presentations were very powerful,” said Dewhurst. “The early use of DFMA creates benefits that reverberate downstream with lasting, measurable effects on profitability.” About Boothroyd Dewhurst, Inc. Boothroyd Dewhurst, Inc., was the first company to commercialize Design for Manufacture and Assembly (DFMA) methodologies and software tools, which make it possible to evaluate, estimate, and reduce the manufacturing cost of a product in the design phase through product simplification and cost estimation. Hundreds of Fortune 1000 companies, including Dell, John Deere, Harley-Davidson, and Maytag, use DFMA to cut the costs of their manufactured products and achieve design innovation in their markets. The company was founded in 1983 and received the National Medal of Technology Award in 1991. For more information about DFMA software, workshops, consulting services, and international conferences, contact Boothroyd Dewhurst, Inc., 138 Main Street, Wakefield, R.I. 02879, USA. Tel. (401) 783-5840. Fax (401) 783-6872. Web site: www.dfma.com. E-mail: info@dfma.com. DFMA is a registered trademark of Boothroyd Dewhurst, Inc. |